Cutting punch - DIN 9861 DA | SM 1009

Price on request

Delivery time: 1-3 days working days

| Diameter 1 | Form | Length 1 | Material | Product number | Unit price | Buy |

|---|

with countersunk head and continuous shank

normal version

DIN 9861 part 1, form DA / similar to ISO 6752

Material:

HSS: heavy-duty high-speed steel

Form N: version DA, normal version.

Hardened and annealed,

tapered head hot upset and annealed.

Dia d1 is precision-ground ISO tolerance h6.

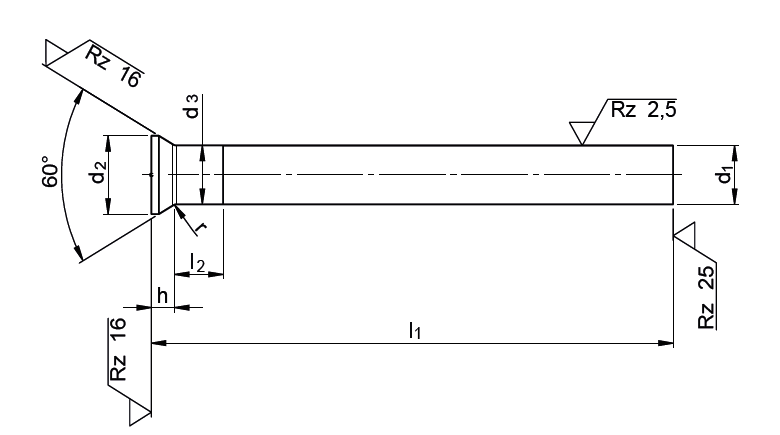

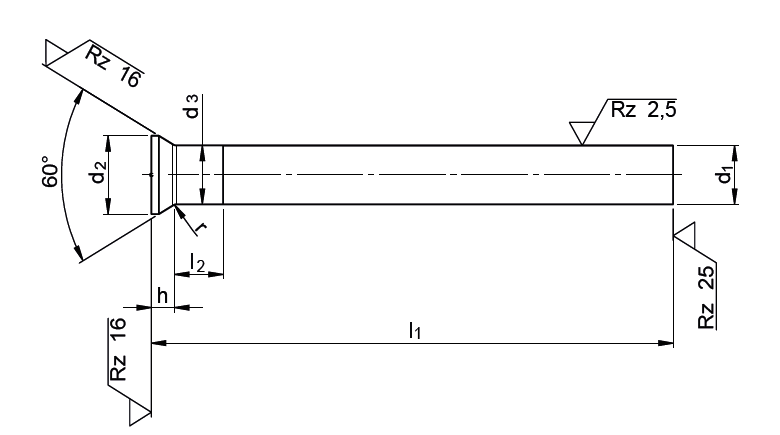

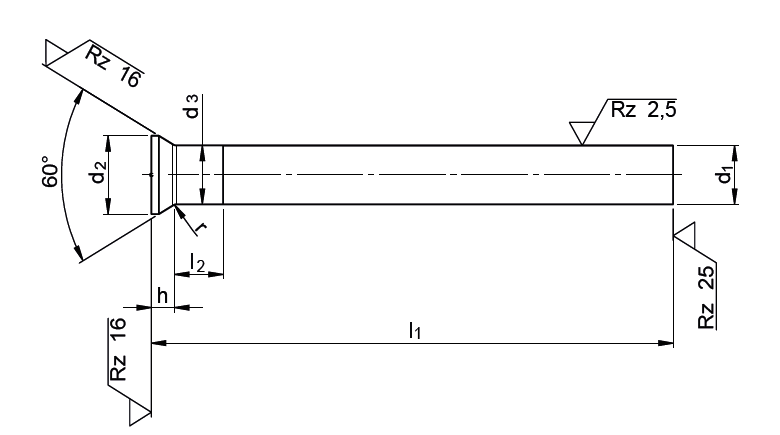

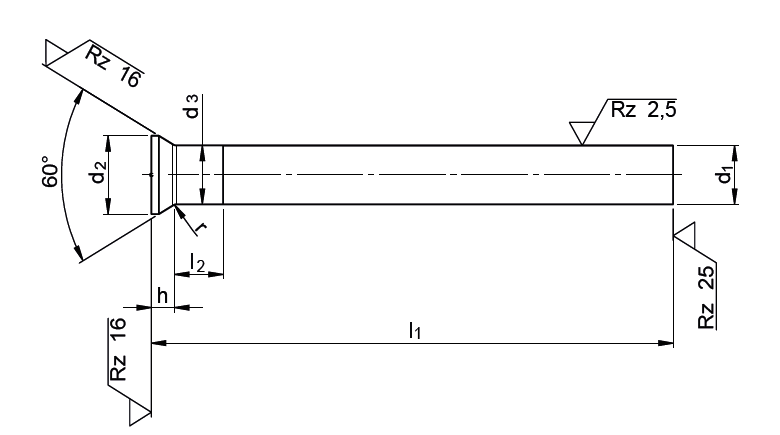

According to DIN 9861 DA with permissible thickening d3 under

the head (see drawing and table).

Hardness:

shaft: HSS, hardened HRc 64±2

head: HSS, hardened HRc 50±5

For high stress, following materials are available on request:

ASP (powder-metallurgically produced high-speed steel)

HSS-nitrided (titanium nitride coatings)

ASP-nitrided (titanium nitride coatings)

TIN-punch(HSS or ASP with titanium nitride coatings)

TK-punch(HSS with titanium carbonitride coating)

Ferro-Tic (or Ferro-titanite)

Metal carbide (powder-metallurgically produced non-ferrous material)

RoHS-compliant: yes

Cutting punch SM 1009 according to DIN 9861 DA / similar to ISO 6752 with conical head and continuous shank

are widely used in industrial sheet metal processing, especially for punching and cutting metals.

They are manufactured with high precision, are durable, and can be used to process even hard materials efficiently.

Typical areas of application include the automotive industry, mechanical engineering and electrical engineering.

Form - : version D - Quality version see SM 1009 D.

| DIN / ISO: | DIN 9861 Teil 1, DA |

|---|---|

| Element type: | Cutting punch |

| Material: | High Speed Steel, Steel - hardened |

| Speciality: | Countersunk head, Head upset |

| Surface: | grinded |

Similar Items